Regarding the service life of sandblasting hose, it is recommended to use Litong customized UPE sandblasting hose for continuous operation environment. Of course, before the sandblasting operation, checking the wear of the joint is also a maintenance technique to improve the service life of the pipe body. In addition, different brands of sandblasting equipment and sandblasting hoses have different types of joints. You can confirm with your account manager before choosing to buy, or customize special joints. The selection of oil extraction hoses should select different hose assemblies according to the different media to be transported and different working pressure levels to prevent different media from eroding the pipe body and media leakage, resulting in undue losses and vicious accidents. Accidents caused by improper selection of oil hoses occur from time to time. Generally, substitutes cannot be used, and they need to be specially managed and used properly to avoid accidents.

Over the past 17 years, Litong Hydraulics has insisted on taking continuous innovation and development as an opportunity to promote product technology innovation, accelerate the pace of new product development, and actively attract outstanding talents. Now it has 55 technicians with a master's degree or above, and the R&D team and Qingdao University of Science and Technology established Rubber Research Institute, strengthen school-enterprise cooperation, adhere to research and development innovation, continue to launch new products, launch new fluid solutions, and have a complete service team. Corrosion-resistant chemical hose Drinking water delivery pipe: This pipe body is mainly used for suction and discharge of drinking water, but it is also commonly used in construction and industrial temporary water lines. The diameter of the pipe body is the one that can support customization. The material selection of the pipe is strictly in accordance with food-grade standards. The interior is made of white NR rubber that meets the requirements of FDA and 3A, and the outer layer is made of wear-resistant, oxidation-resistant SBR/ EPDM mixed rubber, the color is blue, in order to ensure continuous operation under a constant pressure of 10Bar, the middle layer of the pipe body is reinforced with a fiber textile cord with high tension.

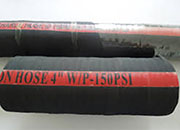

The outer hose of the oil pipe should be composed of oil-resistant, wear-resistant and durable rubber. Along its length, there should be a ribbon on the surface for installation of hoses, editing purposes, drilling hoses, oilfield cementing wire wound drilling glue, repair and petroleum geological exploration, small drilling rigs and water conservancy coal mining, transporting mud, etc. fluid medium. Easy to install and easy to use. PTFE steam hoses are widely used in electronics, electrical appliances, aerospace, petroleum, textile machinery, electrical insulation and other economic fields. It has a fine structure, no mechanical impurities and high strength. It also has very stable chemical properties, corrosion resistance, sealing, electrical insulation and very good anti-aging properties. This hose can be processed into different shapes, such as O-shaped, S-shaped, and other shapes.

More about - corrosion resistant chemical hoses will be updated gradually, so stay tuned. Tags you may be concerned about: hose corrosion resistance chemical

Related tags Article Quantity: Hose (569) Corrosion Resistant (72)