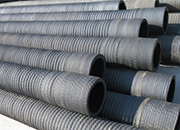

UPE high-pressure multi-functional industrial hoses have a wide range of applications, mostly in steel, chemical, pharmaceutical, etc. The interior of the pipe body is made of UPE material, and the outer layer can be colored according to customer requirements. It is wrapped with ultraviolet, wear-resistant NV or EPDM outer rubber. The tube body can only work at a temperature below 100 degrees Celsius. In order to prevent the body from exploding, it is reinforced with 2-4 layers of steel wire. Black wear-resistant and antistatic NR&SBR synthetic rubber/UPE (the inner rubber material is selected according to the properties of the medium) constitutes the inner layer of the heavy-duty material suction and discharge pipe, and gives it extremely high chemical stability, wear resistance and corrosion resistance. Among them, the inner layer of UPE material with the reputation of "wear-resistant king" makes the heavy-duty material suction and discharge hose far superior to the traditional rubber conveying hose in terms of medium flow rate, wear resistance and aging resistance.

In the construction of the oil hose, construction factors will also affect the corrosion of the pipeline. These construction factors are mainly the quality of the pipeline material and the responsibility and technical level of the construction operators. During the construction of the oil hose, if the construction cannot be The combination of the factors and the specific construction environment will affect the quality of the construction, thus burying the hidden dangers of pipeline problems. Customers sometimes have problems with broken hoses, so the bonding between the rubbers is very important, the bonding between vulcanized rubbers is usually by the bonding method, that is, the adhesive is applied to the surface of the two vulcanized rubbers, and then the vulcanized rubber is bonded. The liquid binder polymerizes. Type and composition of adhesive and bonding process. The deeper the degree of cross-linking of the vulcanized rubber, the poorer the mobility of the molecular chain and the more difficult the bonding.

Single use of EPDM rubber, EPDM rubber + butyl rubber or mixed with appropriate amount of reclaimed rubber are common production methods for high temperature steam hoses. Rubber product manufacturers can choose the appropriate production method according to actual needs. It is worth mentioning that many rubber product manufacturers are still filling a lot of fillers in order to reduce production costs, but too much rubber filler will lead to a significant decrease in the heat resistance of the rubber compound. Our company has always strictly controlled the amount of fillers, and will Add some compounding agents that are beneficial to heat resistance, so the product quality absolutely passes the test. Braided steel wire hoses can be used to transport chemical gases and solvents at high temperature and pressure. In addition, the tube body can provide a flexible connection between the steel tubes in the retention system. It is widely used in mine hydraulic support, automatic hydraulic system of oil field excavator, mining engineering and other industrial fields, especially as a component of jackhammer. The pipe body can continue to work in the environment of -40℃~+100℃, and the maximum temperature is +125℃. The surface of steel wire braided hydraulic hose can be divided into two types: smooth surface and fabric surface.

More about -acid and alkali resistant hose- will be updated gradually, so stay tuned.

Tags you may be concerned about: acid and alkali resistant hose

Related tags Article Quantity: Resistant (536) Hose (569)