Hydraulic Hose Assembly

2022-08-22 15:39:33

If you are not familiar with hydraulic hose assemblies, this article will help you understand the different components in these units. You will learn about Industrial and Hydraulic hose assembly, as well as how to correctly install them. Hose assembly is essential for industrial machines that need to work efficiently. Hoses can be used for a variety of purposes, from lubrication to power transmission. You'll learn how these fittings fit together and what they do when they work correctly.

Hose assembly

The hose assembly holds all of the parts together. It consists of a nut and a threaded nipple. A nut is a fitting that holds hose in place and prevents leaks. The female nut attaches over the tapered surface to the male fitting. Hoses must be sized appropriately for the use they're intended for.

A hose assembly is most often installed in U or loop configurations. This type of configuration enables the hose to be bent and twisted at low temperatures without losing its serviceability. The MAWP (maximum allowable working pressure) is another term used to describe the pressure that a hose assembly can withstand. When measuring pressure, a pressure gauge measures the ratio of the pressure inside an assembly to the external pressure. A pressure proof test, also known by a hose integrity check, is a nondestructive method to test a hose.

Hydraulic Hose Assembly

Proper Hydraulic Hose Assembly requires cutting, fitting, and assembly. To avoid injury, cutting must be done with care. The hose ends should be trimmed cleanly to avoid contamination and hose failure. You should consider the style, working pressure, orientation, and type of fittings that you will require. Also, remember to choose material that is corrosion resistant. These are some tips to ensure a high-quality Hydraulic Hose Assembly.

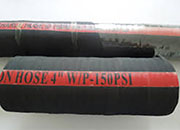

Outer Diameter: The outer diameter is the measurement of the entire cross-section of a hose, including the tube, reinforcement, and cover. This measurement is not the same as the inner diameter because it includes tube features like reinforcements and covers. This measurement is used for sizing the various components of a fitting system. For example, a fitting will fit a hose with a diameter larger than the inside one.

Industrial Hose Assembly

Consider the type of abrasion it will be exposed to, as well as the pressure and temperature. Industrial hose assemblies typically use different types and types of couplings and clamps. As a result, they are not designed to work together very well. Mixing hoses from different manufacturers can be dangerous in small quantities, but it is important to be cautious when using different hoses for the same purpose.

Even though there has been a recent covid-19 outbreak, the market for industrial hose assemblies is expected to continue its strong growth. This is due to commoditization, and will likely negatively impact key manufacturers in this industry. The global market for industrial-grade hose assemblies is expected to grow at 6.3% CAGR through 2021. For this reason, the future of this market is bright. The market's growth is driven by the rising popularity of industrial hose assemblies as well as the emergence new industries.