Steam Hose Features

2022-09-07 09:48:24

There are several features of steam hoses that you should look for before you choose one for your application. These include the ability resist corrosion and the ability of staying flexible even when exposed steam. In addition, you should consider the number of connections on a steam hose. You should also ensure that the hose doesn't interfere or block any other hoses in your facility.

Steam Hose Features

Steam hoses can be used to transport steam and hot liquids from one place to the next. However, not all hoses are equal. Some hoses are oil-resistant while others are not. Regardless of the type of hose you need, there are a few features that are essential to look for.

High-quality hoses are made from FDA-approved materials. Chlorobutyl tubing is highly heat-resistant and EPDM cover materials are excellent for high-temperature applications. These hoses are also resistant against chemicals and ozone. They are also aging and abrasion-resistant.

Steam hoses should have shut-off valves and be protected from kinking. To ensure that the hose is at 45 degrees, a pipe elbow should be installed.

Choose from a variety of steam hoses

When choosing a steamhose, there are many things to consider. These features include compatibility with the media it will be used with, as well as the length of the hose. You should also choose one that is abrasion and corrosion resistant. You should also ensure that the hose has wall linings to protect it from damage.

If you're working with high-temperature steam, you'll need a steam hose that can stand up to its job. A hose that can handle temperatures up to 400°F is a good choice. Versilon steam hoses are tough enough to handle this kind of high-temperature environment, and they're also abrasion-resistant. They have a black inner tube, which is reinforced with steel wire. They also have a maximum working pressure of 250 PSI, and they come in a 200-foot coil.

Steam hoses are durable and can help you save money on your energy bills. Braided steam pipes can help you reduce energy costs as they are less susceptible to heat interference. Unlike ordinary hoses, braided steam hoses are also ozone-resistant, making them safe to use around heat-sensitive materials. Braided hoses are also color-coded and must meet strict safety standards.

Steam hoses are corrosion-resistant

In order to ensure the long-term durability of your steam hose, you need to choose the correct alloy. The alloy must resist corrosive media. Impurities that are present in steam or other corrosive media can cause corrosion of the steel inlays. Corrosion occurs on the inner layer and can cause cracks in the tube. You can prevent this by choosing steam hoses made of galvanized steel.

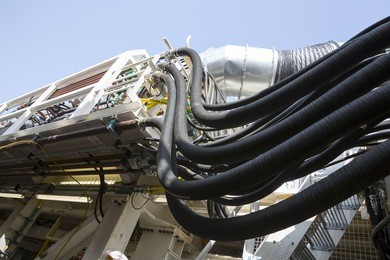

A steam hose has three main components: a media, a reinforcement to provide motion and pressure, as well as a cover. The reinforcement protects against heat, moisture, corrosion, and oxidation. This product is very useful in a variety industries, including chemical manufacturing and textile production.