Corrugated Hose: Design, Properties and Applications

2023-04-21 09:02:33

Corrugated hoses are specialized hoses that are characterized by their flexible, corrugated design. The corrugations provide the hose with increased flexibility and allow it to bend and flex without kinking, making it ideal for use in applications that require high flexibility and strength.

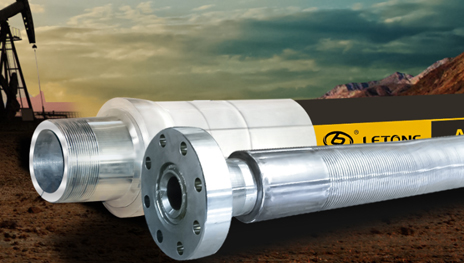

Corrugated hoses are typically made from materials such as stainless steel, aluminum, or plastic, which provide excellent corrosion resistance and durability. The corrugated design also provides the hose with increased tensile strength, making it ideal for use in high-pressure applications.

One of the main advantages of corrugated hoses is their ability to handle a wide range of temperatures and fluids. They are commonly used to transport liquids, gases, and other substances that may be hot, cold, or corrosive. They are also used in applications where there is a need for vibration dampening, noise reduction, or flexibility.

Corrugated hoses are used in a variety of industries, including aerospace, automotive, chemical, and petrochemical. In the aerospace industry, corrugated hoses are used to transport fluids and gases in aircraft, while in the automotive industry, they are used in exhaust systems and cooling systems.

In the chemical and petrochemical industries, corrugated hoses are used to transport corrosive substances and chemicals. They are also used in cryogenic applications where low-temperature fluids must be transported. In addition, they are used in food processing and pharmaceutical applications where sanitary and hygienic transport of fluids is essential.

In conclusion, corrugated hoses are versatile and durable hoses that are widely used in various industries. Their corrugated design provides them with increased flexibility and strength, making them ideal for use in high-pressure and high-temperature applications. They are commonly made from materials that offer excellent resistance to corrosion and other environmental factors, ensuring long-lasting performance. When selecting a corrugated hose, it is essential to consider the specific application requirements and choose the right material and design to ensure optimal performance and safety.