Resin hose cleaning method

2023-05-06 14:48:34

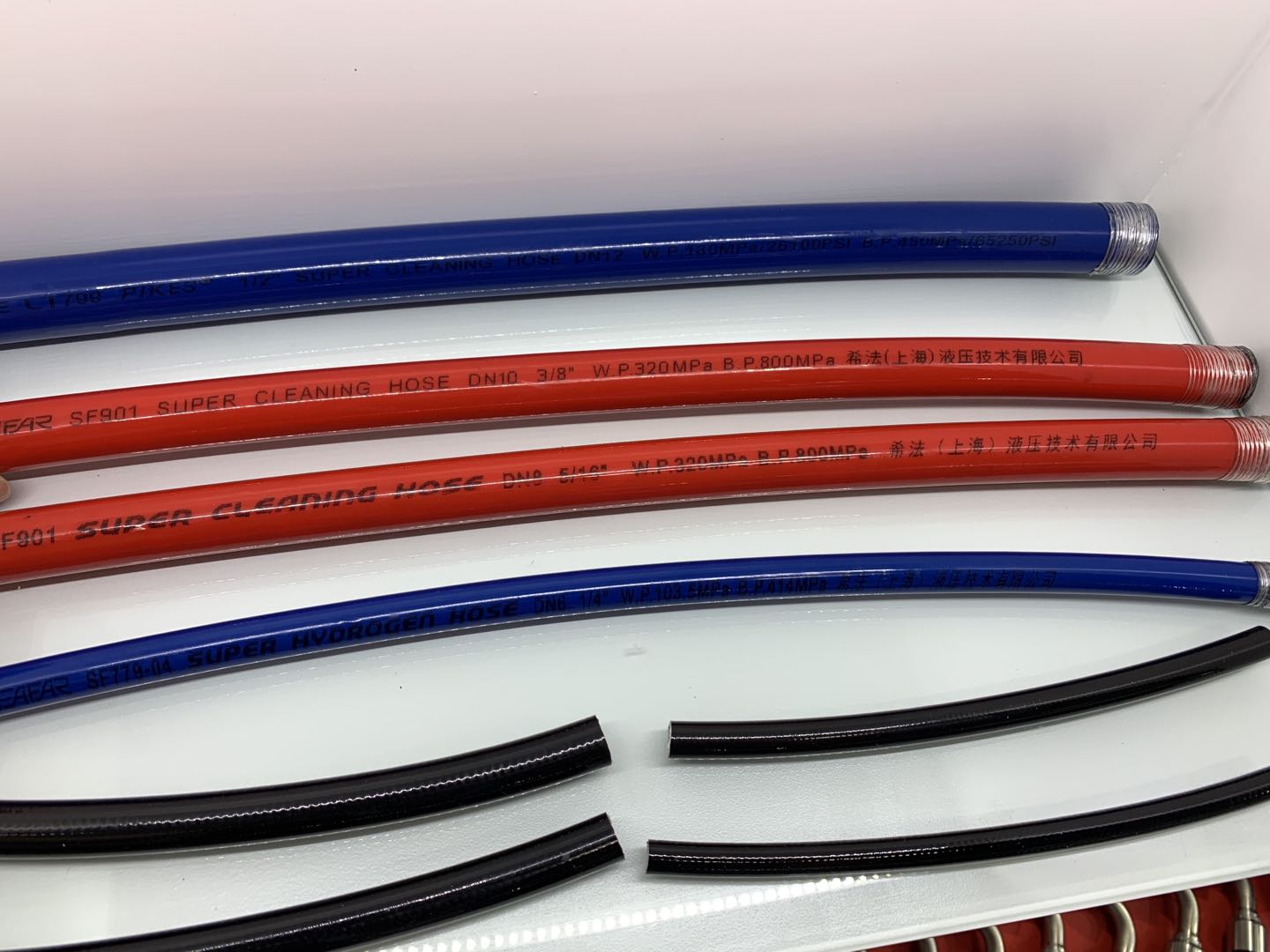

Resin hose is a hose commonly used to transport chemical liquids, drinking water and industrial waste water, etc. Due to the smooth inner wall of the resin hose, it will be blocked or polluted by sediment, bacteria and other reasons after a long time of use. In order to ensure the normal use of the resin hose, it needs to be cleaned regularly. The method and precautions for cleaning the resin hose will be introduced below.

1. Resin hose cleaning method

acid-base cleaning

Acid-base cleaning method is a more commonly used resin hose cleaning method. First of all, all the water in the hoseline needs to be drained, and then an appropriate amount of dilute acid or dilute lye (such as hydrochloric acid, sulfuric acid, sodium hydroxide, etc.) After a period of time, drain the solution and rinse it repeatedly with clean water to thoroughly clean the inner wall of the resin hose.

High pressure water jet cleaning method

High-pressure water jet cleaning is a relatively fast and efficient cleaning method for resin hoses. The inner wall of the hose is cleaned by high-pressure water jet to remove the dirt and sediment attached to the hose. When using high-pressure water jet cleaning, it is necessary to pay attention to the use of appropriate water pressure and water volume, so as not to damage the inner wall of the resin hose.

spray cleaning

The spray cleaning method is a simple and easy cleaning method for resin hoses. Fix the nozzle on the hose opening, spray the cleaning solution evenly on the inner wall of the hose, wait for a period of time, and then rinse it with clean water. This cleaning method can be carried out without removing the hoseline, which is very convenient.

2. Matters needing attention

It is necessary to remove the water in the hose before cleaning, so as not to mix the cleaning liquid with water to produce a chemical reaction, resulting in reduced cleaning effect or damage to the inner wall of the resin hose.

During acid-base cleaning, it is necessary to select a suitable acid-base solution for cleaning according to the material of the inner wall of the resin hose and the conditions of use, so as to avoid damage to the resin hose.

When using high-pressure water jet cleaning, it is necessary to pay attention to the control of water pressure and water volume, so as not to damage the inner wall of the resin hose or form a "water hammer" phenomenon.

The cleaning solution needs to stay in the hoseline for a certain period of time in order to fully react with the dirt and sediment on the inner wall of the hoseline to achieve a thorough cleaning effect.

When the cleaning fluid is discharged, it is necessary to pay attention to environmental protection issues to avoid pollution to the environment.

Thorough flushing is required after cleaning to remove dirt and sediment from the cleaning fluid and hoses.

Regular resin hose cleaning is a key measure to ensure the normal use of the hose and prolong the life of the hose. It needs to be cleaned according to the specified time to avoid problems such as blockage and damage to the hose.