How to Install Hydraulic Pipe

2023-07-05 11:07:28

Hydraulic piping is used in a variety of applications. It transfers energy-generating liquid between systems to function as a full hydraulic circuit.

It has three basic parts: an inner tube, a reinforcement layer and a protective outer layer. The inner tube is usually made from thermoplastic or synthetic rubbers. It is designed to be compatible with the fluid it carries, while offering free-flowing elasticity and pressure-resistant stress bearing.

What is a hydraulic pipe?

A hydraulic pipe is a tube used to transport fluids between components. It is designed to withstand a certain amount of pressure and can be made of various materials. It is a very important part of a hydraulic system and is able to bend around corners and across long distances.

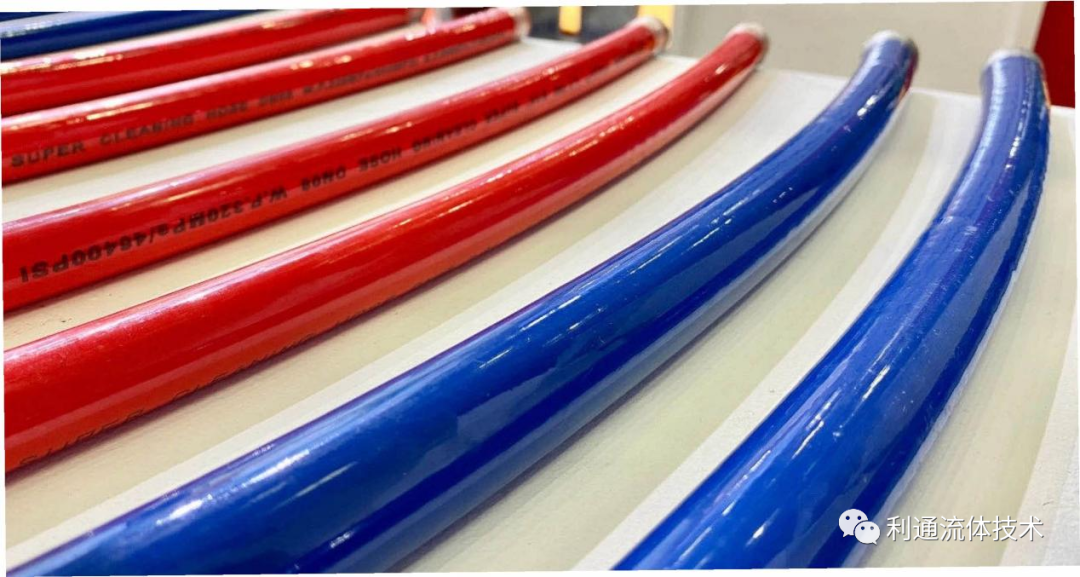

There are three basic parts to a hydraulic hose; an inner tube that carries the liquid, a reinforcement layer and a protective outer layer. The inner tube is usually composed of thermoplastics or synthetic rubbers. The reinforcement layer is often a sheath of braided wired, spiral-wound wire or textile yarn. The protective outer layer is designed to resist oil, chemicals and weather.

A pipe or tube is unable to bend or twist as easily as a hydraulic hose. This can be problematic when a machine like a construction digger requires freedom of movement to operate the tool arm. This is why the majority of hydraulic systems use a combination of pipes, tubes and hoses.

Types of hoses

Hydraulic hoses are the heart of many industrial systems. Few engineering components can be expected to handle the varying temperatures, high pressure levels and contorted positions that hydraulic hoses often work in. They must meet strict standards and be flexible enough to adapt to a variety of applications.

The inner core of a hydraulic hose is typically made from a synthetic rubber, thermoplastic or PTFE material. Its strength depends on the middle layer, which is woven with either textile braid or steel wire. The hose’s outer covering is designed to protect it from extreme temperatures and external pressure, as well as from sharp objects and abrasion.

Hydraulic hoses come with various couplings that connect them to the system and each other. There are two general types of field-attachable couplings: screw-together and clamp-type.

Types of tubing

There are several types of hydraulic piping available, each designed for a specific purpose. The most common is the hose, which conveys high-pressure oils or water between pumps and actuators. The hose is composed of three layers, with the inner layer coming in direct contact with the liquid. This layer is made of a material that is chemically compatible with the fluid. The reinforcement layer is then surrounded by an outer cover that is usually flexible or stiff depending on the application.

Tubes are fabricated from steel to withstand high pressure, and they can be connected with flanges or welding nipples. They can also be joined directly by welds, although this is not recommended since it cannot be inspected internally. A fabricated tube may be rounded to increase its surface area or helixed for greater strength. The length of the tube depends on the amount of power needed to transmit the fluid. The curves of a pipe must be gentle enough to avoid friction, which can cause damage or leaks.

Installation

The first step in installing hydraulic tubing is to determine what the proper diameter is for the line. This can be determined by wrapping electrical tape around a section of the tubing and measuring its temperature with an infrared camera. The taped areas should be 7 degrees F (4 degrees C) cooler than the untaped areas. Then, make sure to leave a curve radius of 1.5 times the diameter for the starting point.

Finally, be careful when changing the hoses, and always wear protective gloves and eyewear. Hydraulic fluid can cause serious injuries if it gets on your skin or in your eyes.