Understanding SBR/NR Material Composition

2023-09-15 09:44:40

SBR/NR (Styrene Butadiene Rubber/Natural Rubber) is a common material used in various industries for its unique combination of properties. This article aims to provide insights into the composition, characteristics, applications, and advantages of SBR/NR material.

Composition of SBR/NR Material:

SBR/NR material is a blend of synthetic rubber known as styrene butadiene rubber (SBR) and natural rubber (NR). SBR is a versatile elastomer derived from the copolymerization of styrene and butadiene, offering enhanced chemical resistance and stability. On the other hand, NR is a natural polymer obtained from the latex of rubber trees, providing excellent elasticity and resilience. The combination of these two materials results in a hybrid rubber with improved strength, durability, and flexibility.

Characteristics of SBR/NR Material:

SBR/NR material exhibits a range of desirable characteristics that make it suitable for various applications. The blend offers superior resistance to abrasion, tearing, and weathering, ensuring longevity and durability. The presence of NR contributes to excellent elasticity and resilience, allowing the material to withstand repeated stretching and compression. Moreover, SBR/NR offers good resistance to oils, solvents, and chemicals, making it suitable for applications in industries such as automotive, construction, and manufacturing.

Applications of SBR/NR Material:

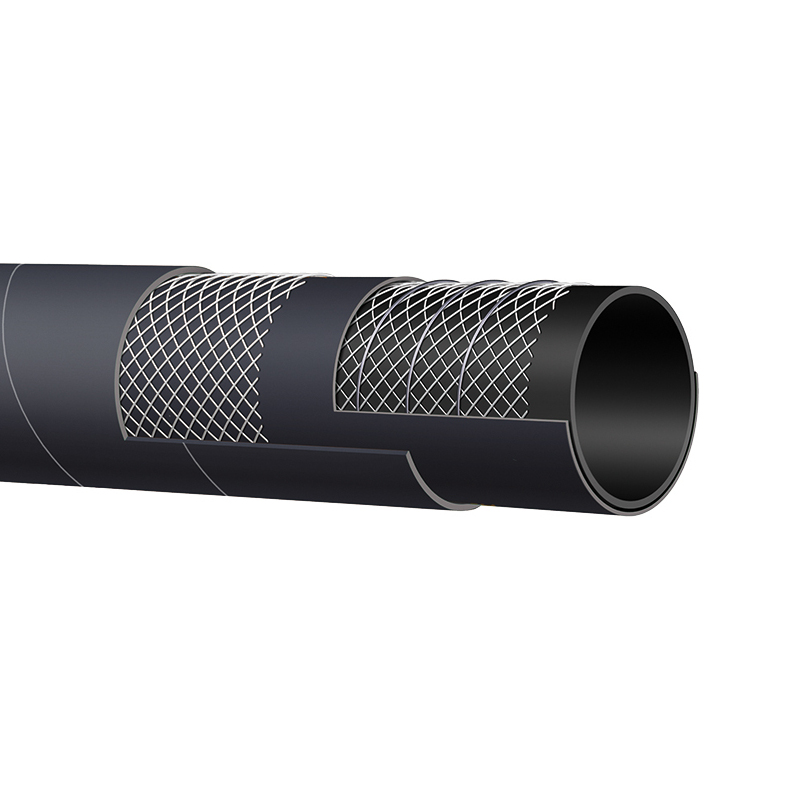

Due to its versatile properties, SBR/NR material finds widespread applications in different industries. In the automotive sector, it is commonly used for the production of tires, gaskets, seals, and hoses, where its durability and resistance to abrasion are crucial. In the construction industry, SBR/NR is utilized for flooring, roofing, and insulation materials, providing excellent weather resistance and durability. Additionally, it is employed in the manufacturing of conveyor belts, footwear, and industrial rubber products due to its flexibility and resilience.

Advantages of SBR/NR Material:

The combination of SBR and NR in SBR/NR material offers several advantages. Firstly, the blend provides a balance between cost and performance, making it cost-effective without compromising on quality. Secondly, the resistance to abrasion and tearing ensures long-lasting performance, reducing maintenance costs. Additionally, the material's good elasticity and flexibility make it suitable for applications that require repeated bending or stretching. Furthermore, SBR/NR exhibits good resistance to weathering, UV radiation, and chemicals, enhancing its overall durability and versatility.

SBR/NR material, a blend of styrene butadiene rubber and natural rubber, offers a unique combination of properties that make it suitable for various applications. The blend's composition provides enhanced strength, durability, elasticity, and resistance to abrasion, tearing, and chemicals. SBR/NR finds utility in industries such as automotive, construction, and manufacturing, where its properties contribute to the production of tires, gaskets, flooring, and other rubber products. The advantages of SBR/NR include cost-effectiveness, longevity, flexibility, and resistance to weathering. Understanding the characteristics and applications of SBR/NR material is essential for selecting the most appropriate rubber material for specific industrial needs.