Chemical hose technology innovation leads the industry development

2025-02-28 13:39:00

With the rapid development of the global chemical industry, chemical hoses, as key components connecting various production links, have become an important driving force for the development of the industry. In recent years, the chemical hose industry has made significant progress in material modification, intelligent application, environmental sustainability, etc., providing safer, more efficient and environmentally friendly solutions for chemical production.

1. Material modification improves hose performance

Material modification is one of the important directions of chemical hose technology innovation. By adding special additives or blending modification, the comprehensive performance of the hose, such as wear resistance, temperature resistance, and aging resistance, can be further improved.

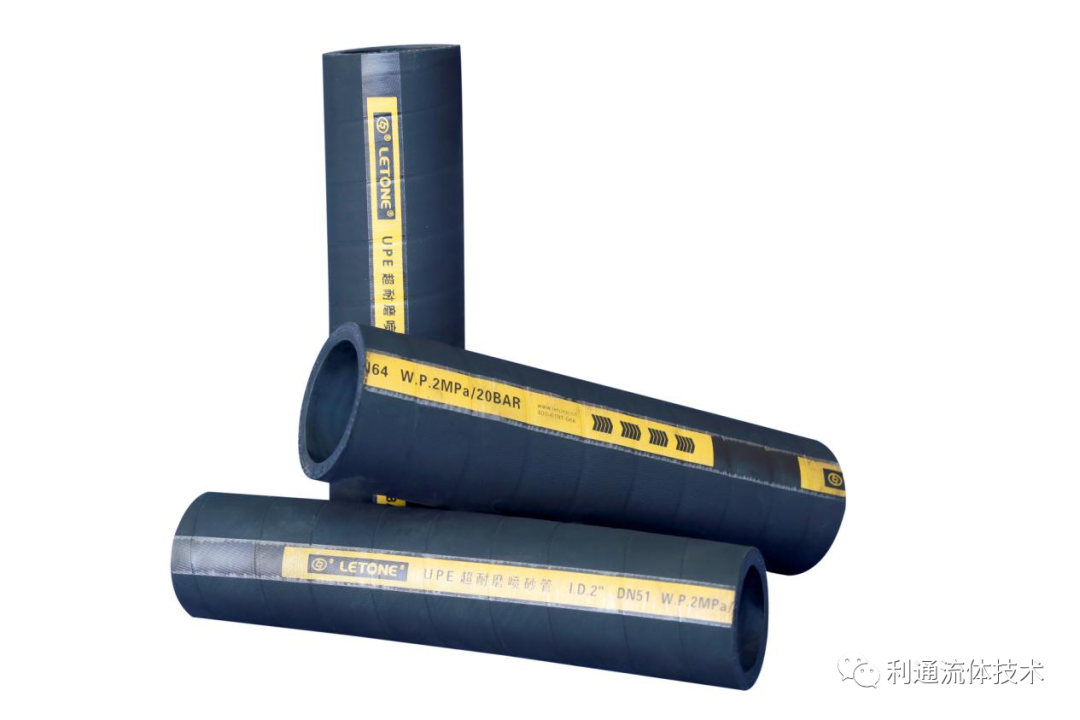

For example, ultra-high molecular weight polyethylene (UPE) hose, as a new generation of chemical pipeline materials, has shown unique value in multiple segments with its excellent wear resistance, self-lubrication and corrosion resistance. Its wear resistance far exceeds that of carbon steel and stainless steel, greatly reducing the replacement frequency and cost caused by wear. In addition, UPE hoses also have good self-lubrication, which can reduce resistance during transportation and improve transportation efficiency.

In addition to UPE hoses, other new materials such as polyimide (PAI) and polyphenylene sulfide (PPS) have also been widely used in the field of chemical hoses. These new materials have excellent high temperature resistance, corrosion resistance and mechanical properties, and can meet the transportation needs under special environments.

2. Intelligent application improves transportation efficiency

The development of intelligent technology has brought new opportunities to the chemical hose industry. By integrating intelligent systems, remote monitoring, automatic control, data analysis and other functions can be realized to improve transportation efficiency and safety.

Some advanced chemical hoses have been equipped with intelligent devices such as pressure sensors, temperature sensors and flow sensors, which can monitor the working status inside the hose in real time. When the pressure, temperature or flow in the hose exceeds the set value, the system will automatically alarm and take corresponding protective measures to prevent safety accidents. At the same time, the intelligent system can also predict the service life of the hose, reminding users to replace aging hoses in time to ensure the continuity of the transportation system.