Nylon reinforced polyurethane hose: performance in multiple fields

2025-06-26 15:44:45

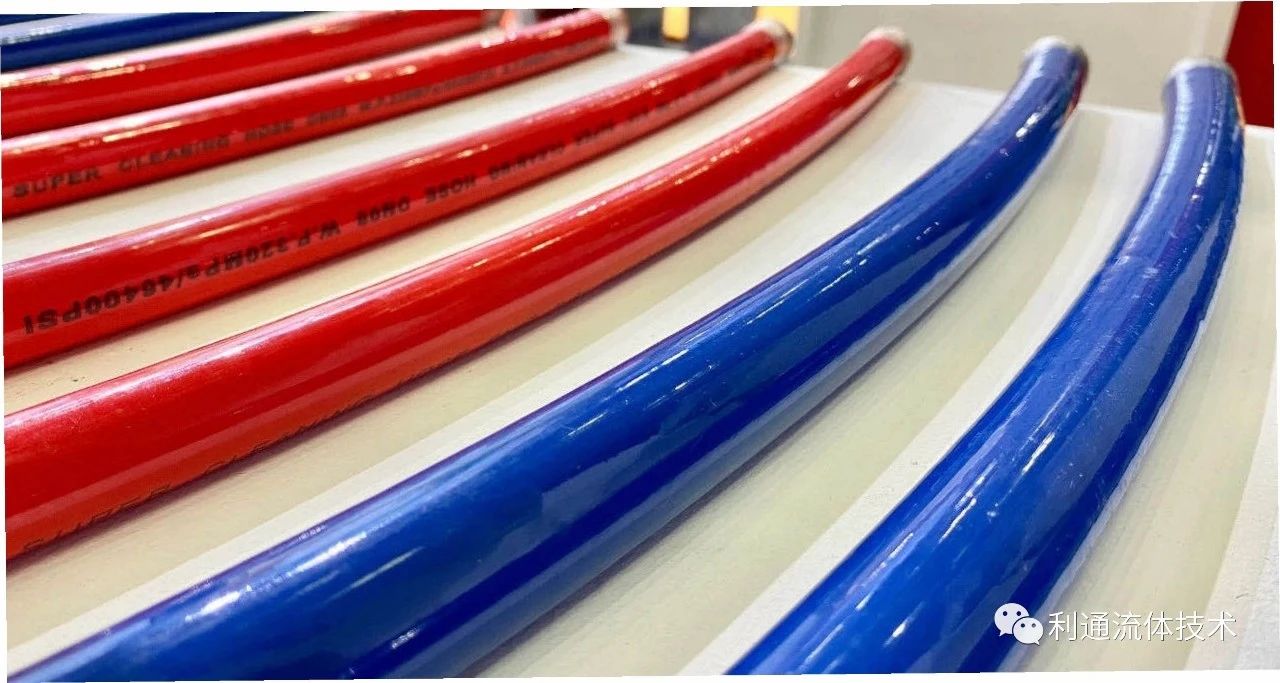

Nylon reinforced polyurethane hoses have been rapidly popularized in many industries in recent years. They combine the advantages of nylon and polyurethane and have become an indispensable material in many industrial applications. In order to help readers understand this material more comprehensively, this article will explore its performance characteristics, application areas and purchase recommendations in depth.

1. Material properties of nylon reinforced polyurethane hoses

Nylon reinforced polyurethane hoses embed high-strength nylon fibers into polyurethane substrates. Through the combination of the two, a hose structure with both flexibility and strength is achieved.

1. High wear resistance: Polyurethane materials are known for their excellent wear resistance, which allows nylon reinforced polyurethane hoses to maintain stable form and function even when used in high-friction environments for a long time.

2. Tensile strength and flexibility: The addition of nylon fibers enhances the tensile strength of the hose and greatly improves the durability of the hose during use. At the same time, its flexibility is excellent, and it can be easily used even in complex installation environments.

3. Chemical resistance: The hose can resist a variety of chemicals, including oil, grease, and many commonly used chemical solvents, and is suitable for a variety of harsh chemical environments.

4. Temperature tolerance: This hose can not only withstand high temperatures, but also exhibits good low-temperature toughness, which is suitable for working environments with drastic temperature changes.

2. Application fields of nylon reinforced polyurethane hoses

With its excellent performance, nylon reinforced polyurethane hoses are widely used in various fields. The following are some typical applications:

1. Industrial manufacturing: In the industrial manufacturing process, equipment needs to transport various gases and liquids, and there are usually fluctuations in temperature and pressure. Nylon reinforced polyurethane hoses can not only withstand these fluctuations, but also can be used normally in complex industrial environments.

2. Agricultural field: In agriculture, irrigation hoses need to be wear-resistant and able to resist the erosion of chemicals such as pesticides. Nylon reinforced polyurethane hoses are very suitable for applications such as agricultural irrigation due to their excellent wear resistance and chemical resistance.

3. Automobile manufacturing: In the automobile industry, hoses used to transport gas and liquid substances need to have high wear resistance and high temperature resistance. Nylon reinforced polyurethane hoses meet these requirements and are therefore widely used in various automobile pipelines.

4. Construction industry: The hoses required on construction sites must not only be wear-resistant, but also withstand pulling in complex environments. The high tensile strength and flexibility of nylon reinforced polyurethane hoses make them very suitable for use as conveying pipes in the construction industry.

III. Recommendations for purchasing nylon reinforced polyurethane hoses

When purchasing nylon reinforced polyurethane hoses, buyers should comprehensively consider the technical parameters and actual application requirements of the product to ensure the best use effect.

1. Determine the use environment: Understand the pressure, temperature, friction, and chemical substances involved in the application environment, and select hoses with corresponding parameters based on these conditions.

2. Evaluate quality standards: Check whether the product meets relevant quality certification standards, such as ISO, CE, etc. These certifications can ensure the reliability and safety of product quality.

3. Consider the size specifications: Choose the right size hose according to actual needs, including inner diameter, outer diameter and wall thickness to ensure that it is suitable for specific installation requirements.

4. Pay attention to accessory matching: Different equipment interfaces may require specific connector types to ensure that the selected hose and its accessories can be seamlessly combined.

Nylon reinforced polyurethane hoses provide reliable solutions for many fields such as industry, agriculture, automobiles and construction with their excellent physical properties and wide range of applications. By deeply understanding its characteristics and usage principles, users can better play its role in actual applications and ensure the efficient operation of production lines. Mastering the correct purchase and use skills can not only improve the safety of operations, but also greatly extend the service life of equipment and hoses.