API 7K Rotary and Vibrator Drilling Hoses

2023-06-27 09:14:03

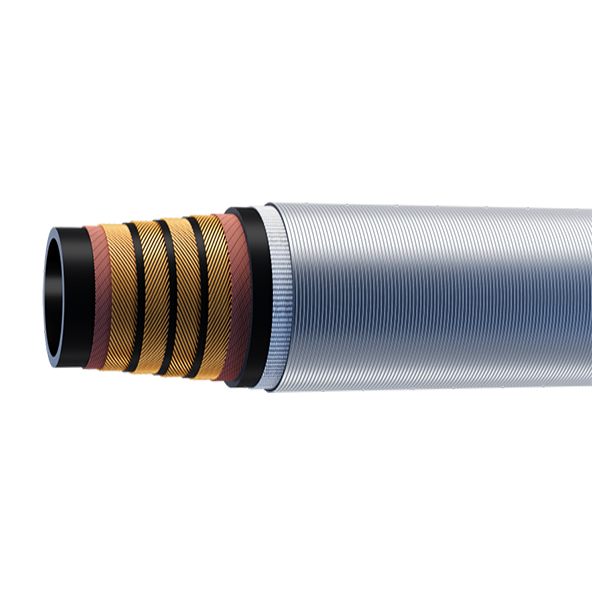

Drilling rotary and vibratory hoses (High Pressure Drilling Hoses) are designed as API 7K spec for pumping mud at very high pressure in oil drilling and exploration. They are also known as kelly hose, cement hose or shock resistant hose.

These hoses are highly flexible and maneuverable to allow accurate positioning of the drill. They are resistant to abrasion, corrosion, cutting, gouging and oil.

Tube

Our drilling rotary/vibrator hoses (High Pressure Drilling Hoses) are designed as API 7K Spec as the flexible connection between standpipe and swivel or between pump and standpipe for pumping mud at extra high pressure in oilfield rig system. Also called kelly hose, cementing hoses or mud hoses, they are capable of handling up to 4000psi working pressures and are made of special NBR tube with two layers of spiral steel wire winding and oil-resistant synthetic rubber cover.

The NBR tube is modified nitrile, black and specially compounded to resist abrasion, corrosion, cutting, gouging, up to 20% H2S and weather. The cover is abrasion and chemical resistant and features one layer middle rubber placed between steel cable layers. It is bonded to the NBR reinforcement with a film bonding technology to make it a complete and sound construction. The hose has built-in male API thread and can be supplied with flanges, unions or couplings on request.

Reinforcement

Rotary hose also known as Kelly hose, jumper hose or cement hoses conveys drilling fluids from the top of mud standpipe to rotary swivel on rigs. It is made of multiple layers of polyester cord over tube and high tensile steel cables. It is oil and abrasion resistant and can be used in low to high pumping pressures. It has a protective breaker fabric over the tube to improve adhesion to body plies.

It is available with a full range of API end fittings including hammer union, camlock and flanges. It can be supplied in any length between 5ft and 90ft. It is recommended for high pressure rotary service in drilling and exploration work. The hose should be properly handled or stored to avoid kicking or crushing which will substantially decrease its rated pressure. The hose should be protected from exposure to sunlight, heat or freezing temperatures. All hoses are subject to inspection and testing prior to shipment.

Cover

Drilling rotary and vibrator hoses (High Pressure Drilling Hoses) are designed as API 7K spec as the flexible connection between the standpipe and swivel for pumping mud at a high pressure in oil drilling and exploration work. It is also called kelly hose, cement hose, or shock resistant hose.

The cover is made from NBR and is specially compounded to resist abrasion, corrosion, cutting, gouging, and weathering. It is also designed to withstand up to 20% H2S and can be supplied with built-in API couplings or flanges.

Vigor Mework Petroleum Equipment Co., Ltd manufactures a wide range of API products including API 6A Wellhead & Christmas Trees, API 6B Gate Valves, API 16C Blowout Preventers and API Rotary/Vibrator Hoses. Our rotary hose is available in customer choke & kill lengths and can be produced in much shorter lead times than our competitors. For more information, please contact us. We are confident that we can provide the quality rotary hose you require at the best price.

Fittings

Rotary drilling hoses (also known as Kelly hose, kelly line, jumper hose, cement hose or mud hose) and vibrator hoses are designed to convey high-pressure drilling fluid. They must be handled carefully to avoid kicking or crushing which will substantially decrease their rated working pressure.

These hoses are built with full-flow API couplings that are integrally secured to the hose reinforcement, with male API threaded ends. They can also be supplied with flanges, unions or swivels on request.

Vigor Mework petroleum equipment manufactures a wide range of oilfield equipment including API 7K Rotary/Vibrator hoses, Choke & Kill manifolds and BOPs. Contact us today for more information about our products and services. We are a professional manufacturer and supplier in China, with many years' experience in this field. We look forward to working with you for a prosperous future! Thank you for visiting our website!